Feed Batching Using Bulk Bags

Micro Ingredient Weighing & Batching System Upgrade

When a leading aquaculture feed producer decided to upgrade its micro ingredient weighing and batching system to improve process efficiency and profitability, it called on Sterling Systems & Controls, Inc. to custom engineer a solution. The feed manufacturer wanted to move away from small bags of ingredients and move to ingredient supply using FIBC bulk bags for ingredient materials where it was practical. Feed batching using bulk bags is doable and done.

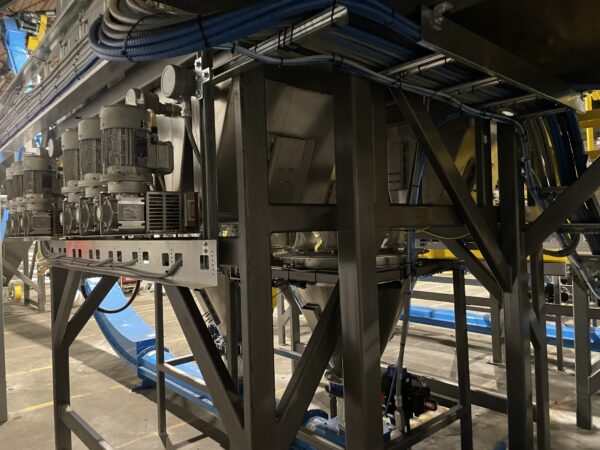

The custom-engineered and manufactured system resulted from the collaboration of Sterling Systems & Controls and customer engineers, including eight (8) bulk bags and twelve (12) stainless steel ingredient bins. In addition, further efficiency improvement was gained by using Intermediate Hoppers and Scales between the micro ingredient batching system and the customer’s filter receivers.

This resulted in the ability to maintain up to three (3) batches in the system created and ready for production at all times; one batch in the ingredient batching system, one in the top intermediate hoppers and one in the lower intermediate hoppers. Batches of ingredients were conveyed via mechanical drag conveyors to the intermediate hoppers after being accurately weighed on multiple scales in the bulk bag (2 scales) and micro bin (2 scales) portions of the system.

The intermediate hopper system includes four (4) scale hoppers, two stacked for the micro bins and bulk bag systems each. The batches are pneumatically conveyed from the intermediate hoppers to the customers’ filter receivers when called for.

The Sterling Systems & Controls ingredient batching system reduces the handling of the ingredients, ensures that the ingredients are weighed accurately and efficiently, and provides tracking capabilities for all ingredients and each batch. The scale hoppers supplied with the system provide high resolution to meet the small inclusion requirements and capacity for typical batch weighments. Accuracy of the weighing of ingredients is typically within +/- .03lbs (0.014kg) from the target weight. Materials that flow inconsistently or have lumps will vary the weighments beyond the system’s control.

The Sterling Systems & Controls micro ingredient systems are unique beyond what our typical competitors supply. As an example, features that separate Sterling Systems & Controls micro system auger feeders from other brands include:

- Industrial bearings are used at both ends of the feeder assembly to support the auger and prevent it from making contact with the auger housing.

- Seals in a seal plate are located between the ingredient material zone and the auger bearings.

- An air gap is provided between the bearings and the seal plates to create a buffer zone to ensure the ingredient materials do not enter the bearings and grease doesn’t enter the ingredient materials.

The augers are a multiple-pitch design to ensure that the weighments are accurate and repeatable batch after batch. The augers are kept in suspension using shaft clamps to ensure that the auger thrust load is not transferred to the drive assembly, therefore increasing drive life. We use shock-absorbing couplings to help reduce the start and stop shock on the motor and drive.

Rectangular to conical discharge scale hoppers are engineered and incorporated into the micro system instead of roll-over-tub scales as the latter cause the ingredient materials to become airborne with a chance that the ingredient material will not be completely discharged for each batch. The conical scale hoppers are a clean design with no ledges and the corners are rolled to ensure that the scale hoppers discharge the entire contents of the scale. Each scale hopper weight is kept to a minimum to increase the resolution of the scale which increases accuracy. Slide gates are not used as they tend to leak after years of use due to ingredient material buildup on the backside of the gate. Butterfly valves are used in place of slide gates.

The frame structure that supports the micro ingredient feed batching using bulk bags is completely independent of the scale hoppers, and the scale hoppers have their frame to support it. This concept allows the bins to be filled during the operation of the system without impacting the ingredient weighments. Other brands use one frame that supports both the bins and the scales, and this can be the cause of bad weighments and unstable scales.

This feed batching system using bulk bags is based on proven designs that increase batch quality and production capacity. The system utilizes feeders that have a unique screw design (as previously discussed) that provides high-speed conveying in the fast mode of operation and excellent repeatability and accuracy in the slow mode of operation.