Bakery Batching

Sterling Systems & Controls, Inc. can offer a bakery batching system and other automated solutions for bakeries and food manufacturing. Receiving of raw materials, batching, weighing, mixing, powder batching systems and the control of other process equipment can be automated. An individual bakery batching system or automation of a combined group of process equipment and systems can be accomplished. Raw material handling systems, e.g. pneumatic and mechanical conveying, liquid weighing and metering systems, bulk bag unloading, micro, minor and major ingredient weighing and batching systems can provided.

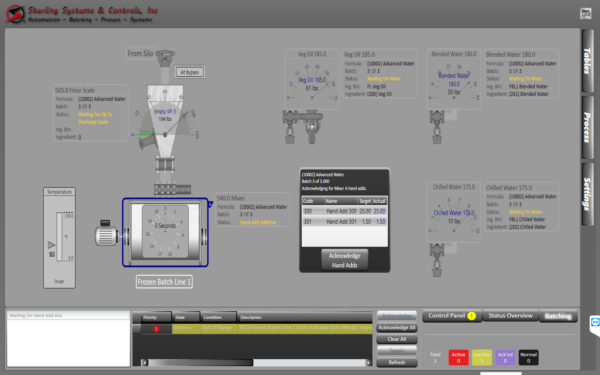

Seamless interaction of all the production processes in the bakery is crucial – and integrated automation with data management and lot tracking provides a perfect answer. We can easily assess your specific needs. Then, we will provide you with the bakery batching system and other necessary production solutions. Also, we can allow users on your corporate network to access data from the batching control system. This allows remotely managing the bakery batching system’s ingredients, formulas, bin assignments, schedules, and other data tables. Also, it allows users to view and print historical batching and process data reports. Users can monitor key processes and batching data and alarm conditions within the control system. They can provide logs and historical analyses of this data as well.

Our PC and PLC control systems are great at controlling process equipment and managing process data, whereas your business system hardware and databases are good at managing administrative and financial functions and data. Sterling Systems & Controls, Inc. can provide the means to bridge these two worlds. This provides a seamlessly integrated solution. You will benefit from efficient bakery production processes that deliver maximum quality at reduced cost.

Proven Bakery Batching System for:

- Bread.

- Bagels.

- Bread Crumbs.

- Pizza Crust.

- Cookies.

- Donuts.

- Waffles.

- Cones.

- Pretzels.

- Snack Foods.

Automating the mixing or blending process is one example. One such solution is summarized here.

Features:

- Scheduling.

- Formulation Management & Storage.

- Raw Material Management, Inventory and Usage.

- Material Parameters (Tolerance, Feeder Speed, Jog, Pre-act/Cutoff).

- Lot Tracking (Bar Code, RFID).

- Validation (Bar Code, RFID).

- Equipment Parameters (Scales, Mixer, Dry Ingredient Feeders, Liquid Meters).

- Temperature Monitoring.

- Mixer Load Tracking.

- C02 System Automation.

- Finished Batch Tracking.

- Abnormal Condition Alarms and Tracking.

- Remote Process Status & Data Access Software (WebCentral).

- Troubleshooting & Diagnostics Features (Local & Remote).

- Bulk Conveying System Automation.

- Bulk Liquid Handling System Automation.

- Micro, Minor, Major Ingredient Automation.

- Semi-Automatic: Manual Prompting & Weigh Station Automation.

- Mixer Automation (Two Speed).