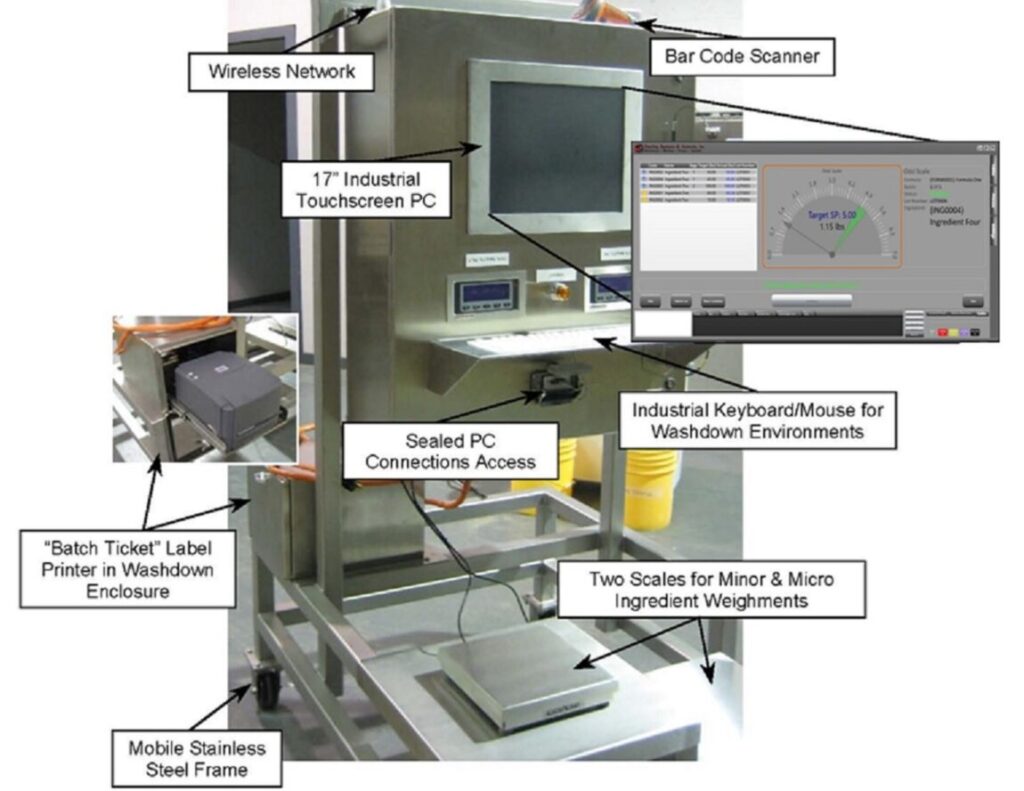

Hand Prompt Batching Station

Sterling Systems & Controls, Inc. designs and manufactures semi-automatic hand prompt batching stations to meet the specific requirements of each customer as needed. The semi-automatic hand prompt batching station serves a wide range of applications where the negative effects of time-consuming and problematic manual batching need to be eliminated. And unlike manual weighing systems available from others, the Sterling Systems & Controls semi-automatic hand prompt batching station will uniquely adapt to your existing process. While it promotes your process of continuous improvement, the semi-automatic hand prompt batching station does not necessitate you consider process changes.

The Sterling Systems & Controls hand prompt batching station is a semi-automatic batching system providing automated operator instructions or prompting, ingredient validation and lot tracking, automatic weighing with over/under tolerance control, etc. This system uses operator involvement to assist in the batch creation and will eliminate bad batches that result from operator error and interruption that occurs in the manual batching process. The operator no longer needs to have a written or printed recipe/formula or keep track of where he is in the batching process as the semi-automatic hand prompt batching station does that for him automatically. No missed ingredients! No bad batches!

The semi-automatic hand prompt batching station uses a high quality professional SQL database for data storage and management. This means you increase your ROI as you grow your production capacity requirements for an automatic minor or micro ingredient batching system. The SQL database will evolve to your automatic system as you grow. This will reduce operator training and your system familiarity with the automatic batching system. The hand prompt batching station evolves and lives as your business grows!

The Sterling Systems & Controls semi-automatic hand prompt batching station (shown with options above) will instruct the operator to weigh ingredients. The Sterling Systems & Controls semi-automatic hand prompt controller will sequence an operator through a recipe/formula one ingredient at a time. A primary advantage of the batching station is to ensure that each ingredient is added to the container, is within a programmed weight tolerance, and from the correct ingredient lot before the controller will index to the next ingredient to be added. This will ensure the validity of all batches created by the operator.

The semi-automatic hand prompt batching station provides real-time records for each batch produced (SQL database). This ensures the highest standards are maintained by ensuring a consistent batched product. As batches are produced, the batching station records the batch data and can print batch reports to a ticket printer (optional). Additional reports and data can be printed on a standard network printer (batching station must be connected to your network) if one is available. The printout provides a hard copy of each ingredient by identification, along with the required and actual formula weights. A time and date is also stamped on each report at the start and end of the batch.

If an alarm condition occurs during batch processing, the Sterling Systems & Controls semi-automatic batching station can print an alarm message, enabling a supervisor to review the performance of the operator and track problems that may occur later. Batching reports can be printed automatically at the end of a batch, or can be recalled and printed on demand through either the semi-automatic hand prompt batching station software or WebCentral (optional Supervisory Control software application). The semi-automatic hand prompt batching station maintains its SQL database by automatically performing routine maintenance and backup procedures.

A barcode scanner (optional) can be attached to the semi-automatic hand prompt batching station control panel using a NEMA4X quick disconnect bulkhead connector mounted on the control panel. A wireless version of the barcode scanner is also available. Prior to any wash down of the batching station control panel, the barcode scanner must be removed.

Ingredient lot numbers are assigned and printed at a remote PC and Printer (by customer or optional) using a custom software package included with the semi-automatic hand prompt batching station. Lot numbers will be 30 characters (or less) long, allowing room for an 11 digit Julian Date/time, 5 digit Vendor Code, and 5 digit Item Code, plus extra characters for future expansion if necessary.

The Sterling Systems & Controls semi-automatic hand prompt batching station will need to be placed on a local customer-supplied Ethernet Network. Any customer PC’s which might be using the optional WebCentral software to communicate with the semi-automatic hand prompt batching station will also need to be on the same network as the hand prompt controller. If an Ethernet network infrastructure is not already in place, Sterling Systems & Controls can assist with specifying networking hardware and cabling if needed. The hand prompt batching station will include an integrated Ethernet Network Adapter, but no other networking hardware is included with the semi-automatic hand prompt batching station.